Creating Sustainable Solutions Through Innovation

We establish strong partnerships with industry leaders to foster innovation and enhance research capabilities. This allows us to conduct applied research aimed at addressing both industry-specific and broader societal challenges.

Recycled Plastic Waste

The construction industry in Singapore relies heavily on imported natural aggregates like river sand and granite gravel. For the industry to reduce reliance on these materials and enhance resource resiliency and sustainability, alternative materials need to be developed to supplement conventional construction materials.

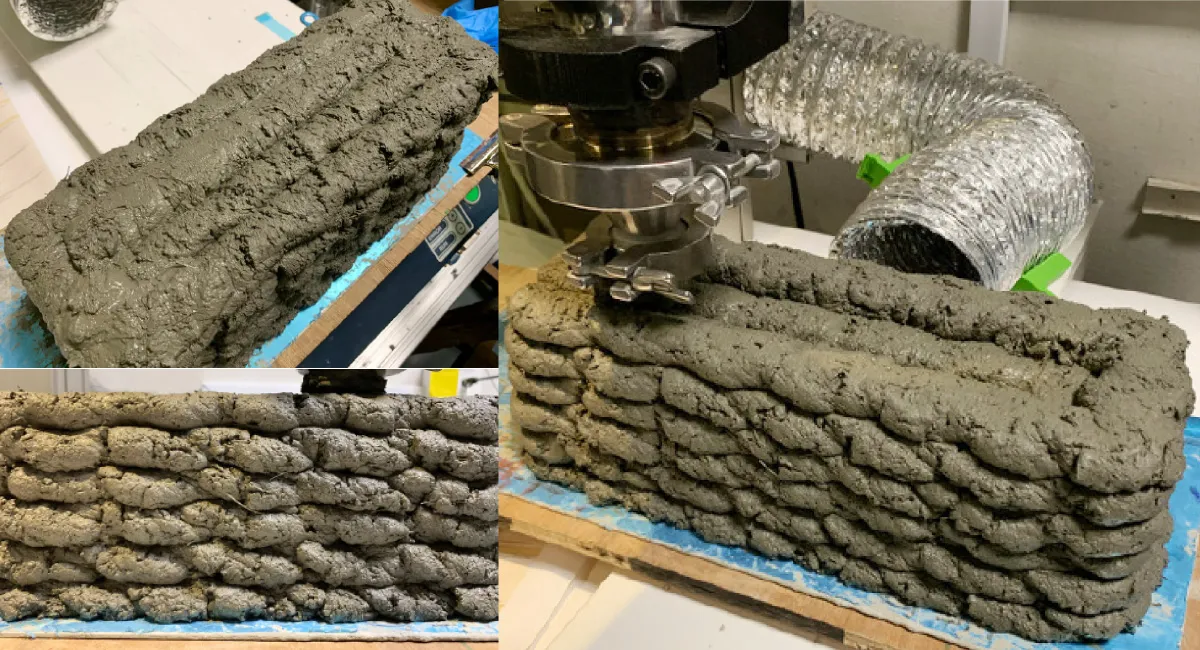

The Centre for Urban Sustainability (CUS), a research centre at Temasek Polytechnic, found plastic waste to be a possible alternative to partially replace fine aggregates in concrete. The research team developed a plastic- concrete mix formulation, in which a portion of the fine aggregate (natural sand) was replaced with plastic waste (polypropylene).

It was concluded that up to 20% of the sand volume in concrete can be replaced with plastic waste for non-structural applications through experimentation. This product is comparable to conventional concrete. It does not incur excessive segregation during casting and possesses high compressive strength as well as durability.

Non-structural concrete prototypes such as precast drain channels kerbs were made using the plastic- concrete mix. A pilot trial to install these concrete segments in a local construction project by Jurong Town Corporation (JTC) is ongoing. Upon completion of the installation works, the durability and environmental performance of the prototypes will also be monitored for a period of 12 months.

CUS focuses on R&D thrusts, namely solid waste management, recycling for strategic building materials and food waste reduction.

TP Design Show 2024

Temasek Polytechnic (TP) showcased the future of design through innovative projects tackling real-world challenges such as sustainability. Over 300 design projects ideated by TP’s School of Design final-year students were on display at the annual TP Design Show from 15 to 20 March 2024.

Demonstrating the future-readiness of TP’s Design School students, the projects challenged them to hone their creative flair and critical-thinking skills, preparing them well for the dynamic and ever-changing future of design.

Examples of key sustainability related projects are:

Sustainable fashion using innovative upcycling techniques and natural dyes;

Smart solutions for kitchen safety and fire prevention from repurposed Singapore Civil Defence Force (SCDF) gear;

A pioneering eco-friendly fishing method that utilises black soldier fly worms as bait to protect ocean biodiversity

Sustainability Design Awards

Sustainability is a core element of TP’s curriculum and is worked into the academic programmes in all our schools, where students are guided to take collective action on sustainability matters. The annual Sustainability Design Award (SDA) is one such effort to recognise creative projects that advances environmental sustainability.

The SDA, back for the 7th run was presented to six exceptional TP student projects at the Opening Ceremony of the Design Show. The 2024 edition of the SDA also featured a brand-new category. For the first time, TP extended the awards to secondary school students, which received participation from 61 teams over 19 schools. Eight winners were awarded and 15 finalist projects were showcased at the TP Design Show.